The following projects are based on catia. This list shows the latest innovative projects which can be built by students to develop hands-on experience in areas related to/ using catia.

The design and fabrication of a braking system is a difficult task. The application of brakes using vacuum in automobiles is a more difficult task in the initial stages of the work. But it has been successfully proved that such brake application is possible with the fail-safe condition. While implementing this idea on a heavy vehicle, it is better to replace the manually operated directional control valve with solenoid operated directional control valve to reduce driver effort and also it will work like a brake pedal switch. In this project, you will design and fabricate a vacuum braking system for a Train.

A Leaf spring is used in a four-wheel automobile vehicle as a part of the suspension system. These springs are generally made from steel, which adds a lot of weight to the vehicle leading to a decrease in the efficiency. In the case of lightweight vehicles, things become worse, as the weight of these spring is too heavy it leads to lower performance. In this project, you are going to solve this problem by designing a leaf spring in a solid modeling software and optimizing your design by varying the dimension and type of composite material so that weight will be reduced without compromising the effect needed from the spring.

In India, pumps are largely used in agriculture and Automobile sector. When it comes to oil pumps it holds 8% of the total market share which is around 700cr. So, having deep knowledge in this field makes an engineer employable. In this project, you are going to work on designing a Gerotor pump and optimizing it so that flow rate can be maximized and flow ripple can be minimized.

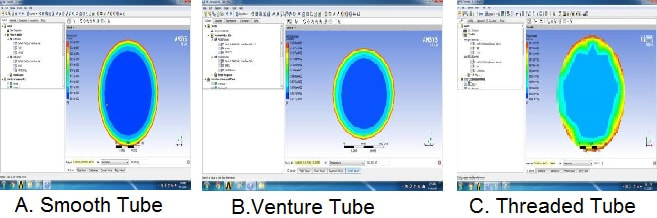

Heat exchanger has been a part of many works producing devices such as air conditioner, refrigerator, automotive, manufacturing, thermal power plants etc. Convective heat transfer is the main phenomena behind the working of heat transfer. A lot of research going on around the world to increase the heat transfer rate of a heat exchanger. One way of increasing this is by introducing extended surfaces inside the fluid flow which will result in more surface area and flow velocity. This technique is known as passive heat transfer augmentation technique. In this project, you will work on increasing the coefficient of convective heat transfer inside a Copper tube using the above technique and will observe the benefits of this technique.

Thrust vectoring is one of the technologies used to overcome the challenge for innovation. By vectoring the exhaust jet, the engine’s thrust is used to control the aircraft. In supersonic fighter aircraft thrust vectoring is one of the major phenomena used for VTOL/STOL and maneuvering. But in commercial aircraft thrust vectoring is used to prevent catastrophic failure and for Short Take-Off and Landing.

Want to develop practical skills on latest technologies? Checkout our latest projects and start learning for free

The VELOCITY-XL aircraft is a long-range aircraft with the latest technology in aerodynamics and structure to provide good maneuverability facilities and stealth mode. This can move 1100-miles cross country trips at speeds above 190 MPH while carrying four adults and baggage in total comfort. These airplanes perform best at altitudes of 8,000-11,000 feet. Landing requires a speed of about 85 MPH and a 1,500 feet long landing strip.

The main purpose of this project is to minimize the loss of life in times of catastrophic failure of the hydraulic system or case of failure of engines. A new design concept that has the potential to save the lives of a thousand passengers in the event of an air crash. The notion involves the redesigning of a plane with the detachable wings that would eject during the emergency to touch down on land or water safety. It is the method of detaching the wings from an aircraft which is in the state of an unrecoverable stall, which could add up to damage in time of catastrophe.

In this project, we are going to fabricate an aircraft with detachable wings and the Orion parachute system (3 parachutes). Later creating a 3D model of an aircraft and run analysis over the model and obtain the results. At last a field test is conducted based on flight data requirements.

The landing gear is a structure, which supports the aircraft in the ground. A major part of aircrafts load is transferred to the landing gear during take-off and landing. These loads are then transferred to the airframe through landing gear beams. Wheels of the landing gear are added as per the size of the aircraft. The position of the landing gear depends on the design, type, and load of the aircraft. Some landing gear is mounted on wing and some under the fuselage.

In this project, we are going to create and analyze a 2D and 3D model of lug attachments in the landing gear.

A variable-sweep wing is a type of wing configuration, that changes the sweep angle of the wing during flight. This is a concept of hybrid wings used for a sudden increase in velocity and aerobatic purpose.

An ornithopter is a type of aircraft that flies by flapping its wings. Designers try to mimic the flight of birds, bats, and insects.

In this project, we are going to design and develop a scaled 3D model of ornithopter resembling an eagle. Then, kinematic data is obtained from the 3D model of ornithopter and fabricated to the required dimensions.

The landing gear forms a structure, which supports the aircraft on the ground. All the load will be acting on the landing gear during take-off and landing. The larger the aircraft more the wheels are added to the landing gear. The position of landing gear depends on the design, load, and type of aircraft. Most of them are mounted on the wing.

A propeller is a distinct type of fan that translates rotational motion into thrust by producing a pressure difference in the nearby fluid. Typical fans and propellers have the same physics, yet a fan is generally still, while a propeller causes the object to be in motion. Propeller is a main component in several industrial designs regarding rotating machinery.

Technological advancement has proved the impossible things as possible. Similarly, the recent innovations in UAV’s (Unmanned Aerial Vehicles) which are commonly known as drones paved the way for the newer way of transportation not only for carrying goods but also to carry humans from one place to another.

Increased usage of Automobiles like cars, bikes in the metro cities escalated the traffic and also increased pollution. To overcome both the issues here we are going to develop a drone project which can able to carry passengers from one place to another like a taxi.

CATIA abbreviates to Computer-Aided Three-dimensional Interactive Application which is best suited for operations like CAD (Computer Aided Designing), CAM (Computer-Aided Manufacturing), PLM and 3D design. In this article, we will make a mechanical design and assembly of universal coupling using CATIA software. While building this project you will be introduced to various concepts of CATIA such as part design, Mechanism design, sheet metal and surface modelling.

Universal coupling or U-Joint or Universal Joint shaft is used to transmit the power through shafts by connecting the shafts in different angles. Which also allows the rear axle to move up and down freely without affecting power transmission. Universal Joints are found in transmission shafts of automobiles, industrial motors, propeller shafts, power transmission shaft of helicopter blades, etc.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

You can build this project at home. You can build the project using online tutorials developed by experts. 1-1 support in case of any doubts. 100% output guaranteed. Get certificate on completing.

Want to develop practical skills on latest technologies? Checkout our latest projects and start learning for free

Join 250,000+ students from 36+ countries & develop practical skills by building projects

Get kits shipped in 24 hours. Build using online tutorials.

Stay up-to-date and build projects on latest technologies